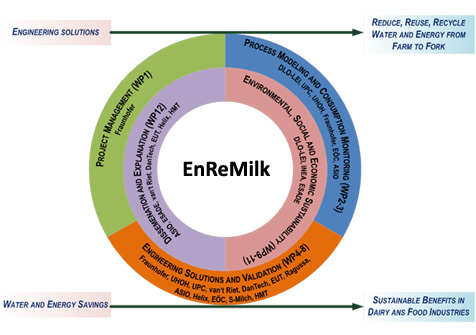

EnReMilk Project

EnReMilk will achieve significant water and energy savings in representative

dairy case studies, mozzarella and milk powder production, across the supply

chain. The dairy industry is an important food industry sector with sales of

€124.3 billion and added value of €17.4 billion p.a. It is a high energy and

water consumer, both overall and per unit production: up to 6.47 MWh (5.55 MWhth

and 0.92 MWhel) and an average of 2 m3 of water per tonne processed milk. 98 % of the fresh

water used is of drinking water quality with 80% of energy consumed in process

heating, pasteurisation, sterilisation, drying and cleaning operations.

During EnReMilk, energy savings of at least 20% and water savings of at least 30% will

be achieved in case studies (3 months production), replicable in both SME and

larger dairies. These savings will be validated against a consumption baseline

of existing operation, being validated in model simulations and in physical

trials. Emerging and novel engineering technologies will be optimised and

implemented in key dairy unit operations to provide significant and simultaneous

saving of water and energy, while ensuring food quality and safety.

In the EnReMilk project, emerging and novel food processing technologies will be optimised and implemented in key food processing unit operations.

- (i) identify and monitor consumption patterns of water and energy streams along the dairy supply chain;

- (ii) evaluate the savings potential of a vast array of technological scenarios through modelling and simulation in two representative dairy sectors; mozzarella and milk powder production;

- (iii) optimise the selected technological approaches with the highest water and energy saving potentials and adapt them to the requirements of the dairy industry;

- (iv) provide strategies for the overall management of resource supply and use, and;

- (v) assess the benefits for food producers and food equipment manufacturers, while reconciling sustainability imperatives